How South Florida Contractors Select Hurricane Ready Roofing

February 12, 2026

Launching Into the Eye of the Storm Ready Roof

Setting the South Florida contractor stage for wind-zone construction

South Florida stands at the nation’s hurricane crossroads, so every roof decision carries community weight. Experienced South Florida general contractors study wind-zone maps before unrolling. They focus on material resilience, anchoring systems, and life-cycle sustainability. Homeowners scanning for a trusted team usually begin with the South Florida hurricane roofing directory. The platform lets residents filter certified pros, compare reviews, and schedule consultations without leaving the couch.

Boca Raton roofs, perched between Atlantic gusts and inland thunderheads, demand engineered confidence. That confidence starts with a crew holding wind-mitigation endorsements and deep local references. By clicking on licensed contractors in Boca Raton for wind-zone roofs, owners instantly view license numbers and insurance proofs. These credentials protect budgets when inspectors tighten standards after every storm season. Ultimately, a qualified South Florida contractor hurricane roofing team brings both craftsmanship and compliance to the conversation.

Why hurricane ready roofing drives current construction trends near you

Regional construction companies near you now treat hurricane ready roofing materials as the headline, not an accessory. Buyers ask first about uplift ratings, then about colors. That shift pushes manufacturers to release impact resistant metal roofing panels alongside wind-uplift tested asphalt shingles. Local designers track these launches through storm-ready roof insights from the South Florida blog. In turn, architects weave stronger roof assemblies into every Delray Beach custom home blueprint.

Builders who adopt these enhancements quickly see market dividends. Insurance carriers often reward homes with waterproof peel-and-stick underlayment and galvanized hurricane clips. Premium reductions matter when policy prices escalate along the coast. Shoppers comparing Boynton Beach renovations notice lower deductibles listed beside upgraded roofs, which nudges sales. Consequently, hurricane ready roofing now defines value as strongly as quartz counters or smart thermostats.

Reading the Florida building code barometer for roof compliance

Every South Florida general contractor keeps a printed copy of the Florida building code within arm’s reach. The chapters on mechanical fasteners and secondary water barriers change frequently as wind-zone data evolves. To stay ahead, teams review annotated summaries like coastal building code essentials for contractors. These resources translate dense statutes into field-ready checklists covering roof decking screws, hurricane clips, and ventilation clearances. With the barometer set that high, guessing is simply not allowed.

Compliance also ripples through project timelines. Permit officers in Palm Beach and Broward scrutinize uplift calculations before issuing a single approval stamp. South Florida Contractors’ internal permit-tracking dashboards alert crews to document gaps, preventing costly delays. When inspectors finally step onto a rooftop, they confirm fastener spacing, sealed flashing, and energy-efficient hurricane roof assembly features. Passing on the first inspection keeps labor on schedule and reputations intact.

Engineering the Shield Anatomy of Miami-Dade Approved Roof Systems

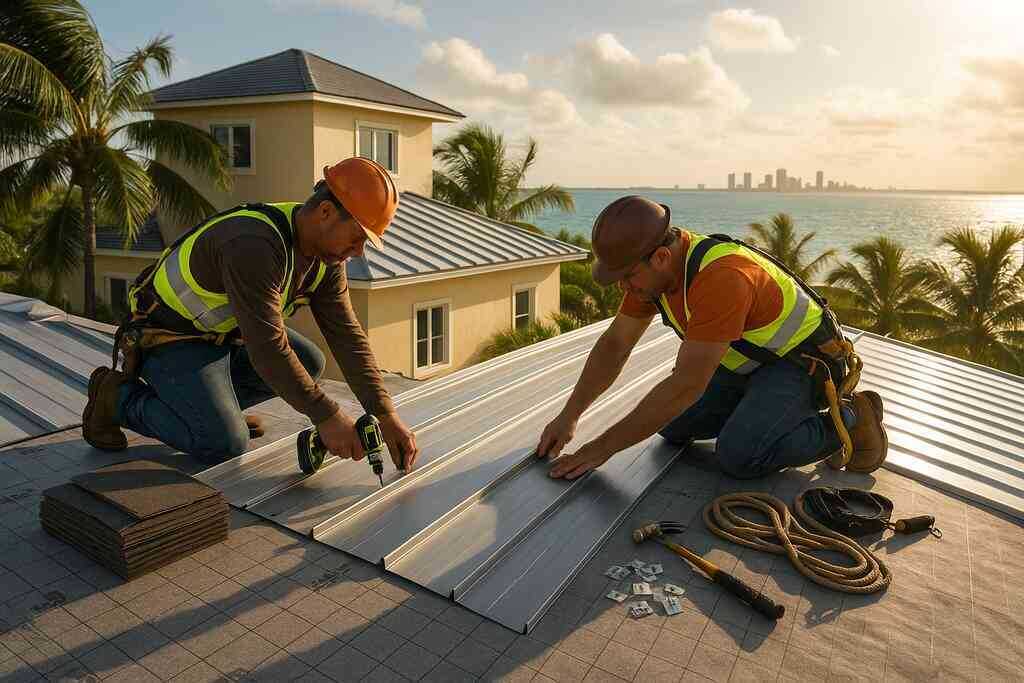

Hurricane uplift anchoring from roof decking screws to galvanized hurricane clips

South Florida contractors treat the connection between the roof deck and the structure as the first defensive line. Crews begin by selecting stainless or hot-dipped screws long enough to penetrate the truss chord, eliminating the withdrawal risk that ordinary nails invite. Next, they map out uplift zones, then place galvanized hurricane clips at precise, code-mandated intervals, producing a continuous load path from sheathing down to foundation. This disciplined fastening pattern converts scattered gusts into distributed structural loads, which keeps rafters from peeling away when shutters rattle. Because Miami-Dade approval demands repeatable lab verification, contractors log every clip lot number to satisfy future inspectors.

Beyond fasteners, seasoned South Florida general contractors calculate uplift resistance using ASCE pressure tables, not guesswork. They simulate corner, edge, and field pressures that intensify around parapets, then coordinate screw spacing accordingly. When numbers reveal a vulnerability, they specify thicker plywood or oriented-strand board, thereby raising diaphragm stiffness. Builders also apply construction adhesives between the deck and truss, adding a monolithic bond that dampens harmonic vibrations during a hurricane’s sustained pulses. Finally, crews photograph hidden hardware before covering it, creating visual proof that permits and insurance adjusters now require for wind-mitigation credits.

Waterproof peel and stick underlayments meeting FEMA compliant standards

Once anchoring ends, moisture control begins. Top-tier construction companies place a self-adhering, modified-bitumen membrane directly over every deck seam, pressing it with rollers until its asphalt matrix fuses into wood grain. This peel-and-stick layer blocks capillary intrusion even if shingles fly away, fulfilling FEMA compliant roof design recommendations for secondary water barriers. Installers lap seams six inches and wrap valleys in continuous sheets to erase weak joints-a detail inspectors frequently flag on lesser roofs. Because South Florida humidity promotes mold, crews choose membranes infused with antimicrobial compounds that resist spore colonization beneath finished coverings.

Temperature also guides material choice. Peel-and-stick products rated for high-temperature environments avoid asphalt bleed-through that can discolor finished metal panels. Simultaneously, low-temperature flexibility protects crews working through cooler pre-storm mornings, preventing membrane cracking during installation. Builders track these specifications in digital checklists, which attach to each project in the South Florida Contractors portal. Ultimately, this water-tight shield collaborates with roof decking screws and hurricane clips, delivering an integrated, energy-efficient hurricane roof assembly capable of surviving wind-driven rain.

Impact resistant metal roofing panels versus wind-tested asphalt shingles

Material selection splits into two dominant camps: impact resistant metal roofing panels and wind-uplift tested asphalt shingles. Metal enjoys a reputation for shrugging off airborne debris, thanks to gauge thicknesses that score high on UL 2218 impact tests. Panels interlock with concealed fasteners, eliminating exposed nail heads that can back out under thermal cycling. Homeowners also appreciate the sleek aesthetic that mirrors Key West vernacular architecture while quietly exceeding Miami-Dade test pressures. Yet metal demands immaculate substrate flatness; therefore, contractors never skip deck prep when specifying standing-seam profiles.

Conversely, premium asphalt shingles remain popular among Boca Raton renovation contractors because they balance cost and performance. Modern laminates feature polymer-modified asphalt and reinforced nailing zones that boost pull-through resistance. Manufacturers now field-test bundles in wind tunnels that replicate 150-plus-mph gusts, a reality coastal buyers respect. Installers lay starter strips with factory adhesive, then hand-seal field shingles using heat guns when ambient temperatures dip, ensuring bond activation long before storm season. Whether metal or composite, both coverings ride atop identical FEMA-rated underlayments, confirming that roof system resilience stems from layered redundancy.

Coastal salt-spray corrosion protection and eco-friendly tile roofing options

Living near the Atlantic paints every fastener and flashing with a fine salt mist that corrodes unprotected metals. To combat that threat, general contractors in South Florida specify panel coatings containing aluminum-zinc alloys enhanced with magnesium for self-healing edges. Flashing, drip edges, and even exposed rafter tails receive the same treatment, forming a uniform corrosion envelope. Where stainless steel is necessary, crews select marine-grade 316 alloys because their molybdenum addition outperforms common 304 in chloride environments. Regular rinse-downs during post-installation maintenance rounds out the anti-corrosion regimen.

For homeowners craving traditional aesthetics, eco-friendly hurricane rated tile roofing steps forward. Lightweight composite tiles mold recycled polymers with ground limestone to mimic Spanish clay without burdening trusses. These tiles pass Miami-Dade impact testing while reducing landfill waste, aligning with sustainable construction standards in Florida. Installers attach each unit using stainless screws and high-density foam adhesives that flex under uplift loads yet rebound when winds subside. As a bonus, composite tile reflects solar radiation better than darker shingles, trimming attic heat gain and supporting energy code compliance.

Flat roof reinforcement with solar reflective hurricane shingles

South Florida’s modern architecture often showcases low-slope or flat roofs, which historically invited ponding water and membrane fatigue. Today, contractors reinforce these planes with tapered insulation that routes water toward oversized scuppers, preventing hydrostatic pressure from testing seams. Over the insulation, they bond modified bitumen sheets coated with ceramic granules that meet cool-roof reflectance thresholds. For projects seeking a shingle look, manufacturers now produce solar reflective hurricane shingles approved for pitches down to 2:12, widening design freedoms without sacrificing resilience.

Attachment matters just as much on flats as on steep slopes. Crews stagger lap joints, embed them in hot asphalt, and then set a mineral-surfaced cap sheet that shields polymers from ultraviolet degradation. Edge metal receives continuous cleats and sealed splice plates, forming a perimeter brace that complements internal anchoring. When homeowners express interest in photovoltaic arrays, builders preload attachment points inside structural drawings, ensuring solar racks connect directly to rafters rather than weakening roof membranes later. This foresight future-proofs homes for renewable upgrades while preserving waterproof integrity.

Roof ventilation science for tropical storms and energy efficiency

A hurricane ready roofing system must exhale heat without inviting wind-driven rain. Balanced intake and exhaust design solves this paradox. Soffit vents admit cooler air under eaves, while ridge vents release attic heat, creating a passive convection loop that stabilizes indoor temperatures. South Florida contractors select vents with internal baffles and rain stops that deflect horizontal water bursts common during cyclones. This technology upholds Florida building code roof compliance, which now quantifies allowable moisture intrusion during dynamic pressure events.

Energy analysts note that every ten-degree attic temperature drop can cut cooling loads by several percentage points. Therefore, builders often pair ridge vents with solar-powered fans that activate when temperatures rise, adding active airflow without exhausting utility budgets. The performance data appear in the energy-smart hurricane roofs guide for homeowners probing deeper into return-on-investment calculations. For immediate project planning, many clients simply type “roofing specialists near me on South Florida Contractors” into the directory and review local ventilation expertise. This targeted search pairs residents with credentialed installers, closing the gap between theory and real-world attic comfort.

The Contractor Playbook: From Permit Desk to Final Inspection

The Contractor Playbook: From Permit Desk to Final Inspection

Navigating the roofing permit process with the South Florida Contractors directory tools

Securing a permit shapes every South Florida contractor’s hurricane roofing timeline, so forward-thinking crews treat paperwork like another trade. They log into the South Florida Contractors directory, pull zip-code specific forms, and preload fields with project data. That digital head start shortens municipal review queues and reduces costly re-submissions. Because Florida building code roof compliance evolves with each storm season, the platform’s alerts flag any new wind-zone calculations before documents reach the city desk. Clients see transparent progress through shared dashboards, which builds trust long before a single shingle lands on site.

Smooth permitting also safeguards budgets. Contractors attach uplift tables for Miami-Dade approved roof systems, plus diagrams showing roof decking with hurricane clips, into one unified PDF. Inspectors appreciate that clarity and often grant over-the-counter approvals for straightforward reroofs. Those faster stamps accelerate material deliveries, letting hurricane ready roofing materials arrive before peak demand spikes. Ultimately, streamlined administration keeps crews on schedule and homeowners calm amid the regulatory maze.

Verifying roofing contractor licenses and targeting insurance premium reductions

Homeowners rarely know where to start with the roofing contractor license verification that Florida mandates. The South Florida Contractors directory solves that confusion by displaying active license numbers beside every profile. Clicking a credential opens state databases in a new tab, proving each general contractor in South Florida for roofing carries proper classifications and has no disciplinary flags. That transparency removes hiring hesitation and discourages unlicensed operators from flooding the market.

Proper licensing also unlocks financial perks. Insurance carriers commonly offer premium reductions when policyholders select contractors certified in windstorm mitigation techniques. Providers recognize that crews who understand FEMA compliant roof design, energy-efficient hurricane roof assembly details, and coastal salt-spray corrosion protection roofing yield fewer claims. By choosing vetted pros, owners position themselves for deductibles that shrink instead of swell after renewals. Documented competence, therefore, pays dividends long after the final inspection sticker dries.

Scheduling reroofing for Boca Raton homes and Boynton Beach windstorm mitigation

Timing a project matters as much as fastening patterns. Experienced schedulers consider supply lead times, forecasted storm windows, and neighborhood association calendars before setting a reroofing Boca Raton homes start date. They prioritize sections most vulnerable to uplift, installing waterproof peel-and-stick underlayment early so sudden squalls cannot sabotage exposed plywood. Coordinated deliveries keep traffic calm on narrow coastal streets and avoid HOA fines for idle dumpsters.

When projects shift south, homeowners searching for windstorm solutions discover windstorm roofing installers in Boynton Beach inside the directory. Those specialists align installation slots with local inspection availability to prevent weather-induced delays. Crews swap design specs on the fly, matching impact resistant metal roofing panels for beachfront lots and wind-uplift tested asphalt shingles for inland tracts. Harmonizing materials and calendar saves residents from frantic, last-minute decisions as hurricane season draws near.

Emergency roof tarping services near me and post-hurricane inspections

Even flawless construction can meet debris the size of car hoods. For that reason, top construction companies near you for hurricane roofs maintain rapid-response units trained in emergency roof tarping services near me requests. They stock breathable, UV-stabilized tarps and screw-through battens that preserve underlying waterproof barriers without tearing shingles. Crews arrive with drone cameras, capturing damage mosaics while ladders still clatter, which speeds claim filing for stressed owners.

After the skies clear, South Florida general contractor teams perform a roofing inspection after a hurricane using infrared scans and uplift-focused fastener checks. They verify ridge vent integrity to protect roof ventilation for tropical storms still ahead. Findings feed into digital reports that outline phased repairs or full hurricane roof replacements in Delray Beach and beyond. This methodical audit turns a chaotic event into a structured recovery plan, reinforcing community resilience.

Warranty strategies for high-wind zones with general contractors in South Florida

A paper warranty means little if wind shear voids clauses, so savvy home builders in Florida specializing in storm roofs craft layered guarantees. Material suppliers back solar reflective hurricane shingles, eco-friendly hurricane rated tile roofing, and flat roof hurricane reinforcement membranes with high-velocity endorsements. General contractors then add labor riders that promise no-leak performance even when gusts exceed code requirements. Coupled together, these dual assurances reduce owner anxiety and heighten resale appeal.

Contract terms also reference scheduled roof maintenance before hurricane season to keep coverage active. Inspections verify sealant elasticity, fastener torque, and any emerging corrosion at flashing. If minor issues surface, crews perform quick touch-ups that qualify as insurance premium reduction roofing upgrades. Owners therefore protect property and wallet through one proactive appointment. In the end, a robust warranty strategy transforms every roof into an evolving shield rather than a static product.

Closing the Loop Building Resilient Skylines One Roof at a Time

Seasonally timed roof maintenance before hurricane season strikes

Proactive roof maintenance before hurricane season starts protects budgets and peace of mind. Experienced inspectors walk every slope, documenting lifted tabs, cracked tiles, and corroded flashing that coastal salt-spray corrosion protection roofing aims to defeat. They probe waterproof peel-and-stick underlayment at eaves, ensuring adhesive seams still grip after relentless humidity. Next, technicians photograph ridge vents to confirm baffles remain clear for balanced roof ventilation during tropical storms. These visual records feed warranty files, anchoring claims if storms later pummel the property.

After the gales pass, teams return for a detailed roofing inspection after a hurricane. They scan sheathing with infrared cameras, spotting moisture hidden under shingles and around roof decking with hurricane clips. If breaches appear, emergency roof tarping services near me dispatch crews within hours, securing breathable covers that will not trap moisture. Quick action stops mold while owners arrange permanent repairs. In turn, comprehensive reports keep the roofing warranty for high-wind zones valid and reassure insurers that the structure stayed code compliant.

Partnering with a South Florida general contractor for long-term storm resilience

Long-term resilience grows when homeowners hire general contractors in South Florida for roofing who specialize in storm science. These vetted professionals carry the credentials that the roofing contractor license verification Florida demands, and they maintain continuing education on evolving wind-zone analytics. Because they install both impact resistant metal roofing panels and wind-uplift tested asphalt shingles, they can match assemblies to your microclimate, not just your budget. Their documentation also secures insurance premium reduction roofing upgrades that counter rising policies.

Strategic partnerships blossom through regional expertise. Homeowners wanting benchmark craftsmanship often consult roof upgrade experts in West Palm Beach when replacing aging decks. These specialists synchronize the roofing permit process in South Florida requires with material lead times, avoiding stressful delays. By coordinating subcontractors, they streamline construction management for reroof projects and keep neighborhoods orderly. As a result, South Florida contractor hurricane roofing alliances deliver airtight timelines and code-correct installations that stand up to the fiercest gusts.

Future-proofing with FEMA compliant design and solar-ready assemblies

Future-ready homes integrate FEMA compliant roof design principles long before panels arrive. Crews start by fastening Miami-Dade approved roof systems along a continuous load path, then overlay hurricane ready roofing materials that include solar reflective hurricane shingles on south-facing slopes. Their cool pigments deflect radiant heat, lowering attic temperatures and supporting energy-efficient hurricane roof assembly goals. When owners crave even greater durability, installers suggest flat roof hurricane reinforcement topped with ballasted photovoltaic modules.

Structural foresight continues under the finish layer. Builders screw down thicker sheathing, then bolster edges with additional roof decking with hurricane clips where suction forces peak. Conduit stubs for future arrays hide beneath ridge caps, making solar upgrades simple when budgets allow. Because every component-from underlayment to flashing-already meets wind-test thresholds, adding panels will not invalidate existing Miami-Dade approvals. This harmonized approach lets home builders in Florida specializing in storm roofs deliver renewable power without compromising safety.

Invitation to explore South Florida Contractors for hurricane ready roofing solutions

A resilient skyline starts with informed choices, and the South Florida Contractors directory roofing search places expertise at your fingertips. The platform lists construction companies near you for hurricane roofs, complete with license numbers, client reviews, and real-time availability. One quick query connects you with Boynton Beach windstorm mitigation roofers, West Palm Beach roof replacement experts, or Delray Beach hurricane roof installation specialists-each vetted for code mastery.

Now is the moment to act. Use the directory to compare bids, schedule free consultations, and set a course for roof maintenance before hurricane season. Whether you need eco-friendly hurricane rated tile roofing, solar-ready standing seams, or a full reroofing Boca Raton homes package, vetted professionals stand ready. With South Florida Contractors guiding every click, your property gains a shield engineered for tomorrow’s storms while elevating today’s comfort and value.

Frequently Asked Questions

Frequently Asked Questions

Question: How do South Florida Contractors vet general contractors in South Florida for roofing to ensure they meet Miami-Dade approved roof systems standards?

Answer: Every company listed in the South Florida Contractors directory must upload an active state license, current insurance, and recent inspection photos that show roof decking with hurricane clips, waterproof peel-and-stick underlayment, and other Miami-Dade approved roof system details. Our review team cross-checks license numbers through Florida’s online database, then verifies past projects for Florida building code roof compliance. Only those South Florida contractor hurricane roofing specialists who pass this multi-layer screening-plus maintain a 4-star or higher customer rating-appear in search results. This means homeowners browsing construction companies near you for hurricane roofs see only proven professionals, not risky newcomers.

Question: The blog How South Florida Contractors Select Hurricane Ready Roofing talks about impact resistant metal roofing panels and wind-uplift tested asphalt shingles. How can I decide which material is right for my home?

Answer: Start by entering your ZIP code in our directory roofing search. We pair you with local West Palm Beach roof replacement experts, Boynton Beach windstorm mitigation roofers, or Delray Beach hurricane roof installation teams who know your exact wind zone. During a free consultation, they compare UL 2218 impact ratings, wind-test data, and coastal salt-spray corrosion protection roofing options. Metal panels excel against flying debris and work well for eco-friendly, solar-ready assemblies, while premium asphalt shingles balance budget and performance with adhesive starter strips and reinforced nailing zones. Your assigned general contractor in South Florida for roofing will also calculate insurance premium reduction and roofing upgrades so you can see the financial impact of each choice.

Question: Can hiring a licensed South Florida contractor through the directory really lower my insurance costs with insurance premium reduction roofing upgrades?

Answer: Yes. Carriers reward FEMA compliant roof design features such as solar reflective hurricane shingles, secondary water barriers, and energy-efficient hurricane roof assembly ventilation. Because our vetted contractors document every fastener pattern, peel-and-stick underlayment, and hurricane ready roofing material in your permit packet, insurers have the proof they need to grant discounts. Many policyholders report double-digit savings after uploading the contractor’s wind-mitigation report generated through our platform.

Question: What steps are involved in the roofing permit process in South Florida and how does the directory simplify it for homeowners planning a reroofing Boca Raton homes project?

Answer: Permitting starts with ASCE wind-uplift calculations, roof plans, and product approval sheets. When you select a Boca Raton renovation contractor from South Florida Contractors, the pro downloads city-specific forms directly from our portal, pre-loads job data, and attaches Miami-Dade approvals in one digital packet. Real-time status alerts keep you informed, so you know exactly when inspectors will check fastener spacing and roof ventilation for tropical storms. The result: fewer re-submissions, faster material ordering, and a smoother timeline that finishes well before hurricane season.

Question: After a storm, how can I quickly access emergency roof tarping services near me and schedule a thorough roofing inspection after a hurricane?

Answer: Open the South Florida Contractors directory on any device and filter for emergency roof tarping services near me. Our system highlights crews on 24/7 standby across South Florida who arrive with breathable tarps, screw-through battens, and drone cameras for damage mapping. Once the roof is stabilized, you can immediately book a licensed inspector to scan for hidden moisture, confirm ridge vent integrity, and recommend flat roof hurricane reinforcement or full replacement if needed. All reports meet the roofing warranty for high-wind zones requirements and speed up insurance claims.

The Contractor Playbook: From Permit Desk to Final Inspection

The Contractor Playbook: From Permit Desk to Final Inspection Frequently Asked Questions

Frequently Asked Questions