What Are Best Pool Deck Options by South Florida Contractors

December 29, 2025

Introduction: Surfacing the Ultimate South Florida Pool Deck

Understanding heat resistant and non-slip priorities under relentless sun

Blazing pavement can ruin even the most festive pool party. Therefore, heat resistant pool decking ranks first on every South Florida pool deck options checklist. Materials like travertine, coral stone, and advanced cool deck coatings reflect sunlight instead of absorbing it. Feet stay comfortable, and surface temperatures drop noticeably compared with standard gray concrete. Thermal comfort also reduces chemical evaporation, keeping your pool chemistry balanced longer.

Safety requires more than cooler toes; it demands a reliable non-slip pool deck surface during sudden rain bursts. Textured travertine, stamped concrete broadcast with silica, or polymeric additives all exceed minimum friction coefficients. A seasoned South Florida contractor tests samples wet and dry to guarantee code compliance. They also consider sunscreen overspray, pool toys, and leafy debris that can create hidden slick spots. That proactive mindset keeps children, guests, and even pets confidently moving around the water.

How a South Florida contractor balances beauty durability and budget

Budget conversations usually open with hard numbers but quickly shift toward lifestyle goals. Families dreaming of sunset yoga sessions demand different finishes than investors flipping a vacation rental. A South Florida general contractor uses product mock-ups to illustrate how color, texture, and joint patterns influence ambiance. They explain why marble may sparkle yet devour contingency funds once sealing, drainage, and labor premiums accumulate. Conversely, stamped concrete can mimic stone for less, freeing cash for outdoor kitchens or smart lighting.

Durability decisions hinge on substrate preparation, installation method, and aftercare. Certified contractors specify proper compaction, steel reinforcement, and expansion joints to avoid the notorious Florida deck cracks. They also choose sealers rated for saltwater friendly decking when pool owners favor mineral sanitation systems. That foresight saves homeowners recurring repair bills and protects family schedules from disruptive maintenance. Ultimately, pairing beauty with resilience requires honest trade-offs best mediated by seasoned professionals.

The rise of luxury pool deck renovation from Boca Raton to West Palm Beach

Luxury pool deck renovation has surged, fueled by remote work flexibility and record real estate equity. Homeowners in Boca Raton, Delray Beach, and West Palm Beach now treat outdoor areas like primary living rooms. Upscale selections, including marble pool deck installation and oversized porcelain slabs, create resort vibes without a passport. Designers blur boundaries further with flush pool coping, hidden drainage, and integrated bench seating. These elements transform a once utilitarian surround into a glamorous social zone.

Yet even glamorous surfaces must satisfy strict hurricane ready deck design standards. High-end clients respect contractors who secure permits, validate wind uplift calculations, and coordinate inspections efficiently. Projects progress smoothly when artisans, suppliers, and engineers collaborate under one accountable South Florida general contractor. The result is a deck that dazzles visitors today and weathers tomorrow’s squalls unscathed. Such success stories inspire neighboring communities to launch their own upgrades, fueling a regional renaissance.

Material Mastery: The Cool Tough Choices

Travertine pavers versus marble slabs picking the right thermal performer

Travertine remains the benchmark for heat resistant pool decking because its porous structure breathes under ruthless rays. Homeowners feel the difference instantly when barefoot on a travertine paver pool deck during peak sunshine. Moreover, the stone’s subtle earth tones pair elegantly with Mediterranean-style homes often built by a seasoned South Florida contractor for pool deck projects. While travertine costs less than marble, it still delivers luxury pool deck renovation flair that boosts resale. Consequently, many Boca Raton pool deck remodel plans begin with a travertine sample board before exploring other choices.

Marble pool deck installation dazzles with a polished sheen that whispers resort prestige, yet thermal comfort can suffer. Contractors combat potential burn risk by specifying lighter hues, energy reflective deck coatings, and generous shade structures. These strategies help marble slabs rival travertine in surface temperature while preserving their mirror-like beauty. Nevertheless, sealing frequencies rise because marble reacts to salt and sunscreen. Clients must weigh those upkeep commitments against the unmatched visual drama marble provides.

Coral stone charm for saltwater friendly decking

Coral stone pool decking once graced historic estates, and its enduring popularity stems from natural slip resistance and coastal character. The material forms in prehistoric reefs, so micro-fossils create gentle traction even when drenched by afternoon squalls. That built-in grip qualifies coral as a dependable non-slip pool deck surface for families with energetic swimmers. Additionally, its alkaline composition deflects corrosion from modern saltwater generators, earning it the title of saltwater friendly decking.

Installation success hinges on sourcing dense blocks and anchoring them to withstand the tropical climate pool deck materials stressors. Experienced Delray Beach pool paver contractor teams pre-blend pavers from several pallets to avoid obvious color banding. They also back-butter each stone with polymer-modified mortar, sealing capillary channels that might invite mildew. Properly installed coral decks survive decades of chloride exposure without spalling. That longevity explains their frequent appearance in West Palm Beach pool deck resurfacing portfolios.

Stamped concrete and cool deck resurfacing reinventing the classic pour

Stamped concrete pool deck systems deliver custom patterns that mimic flagstone, slate, or even tropical wood for a fraction of the price. Creative homeowners choose color hardeners reflecting natural hues, while contractors broadcast silica for enhanced traction. When an existing slab shows age, property managers often find pool deck resurfacing specialists in South Florida to apply polymer overlays that revive aesthetic appeal. These cool deck resurfacing products embed infrared-reflective pigments, dropping surface temperatures dramatically. As a result, renovated pads rival brand-new pours in both comfort and curb appeal.

Beyond cosmetics, modern stamped concrete incorporates micro-fibers and low-shrink admixtures that resist cracking under daily thermal cycling. Control joints align with stress points, preventing random fractures that trap algae. Contractors still advise annual sealing, yet today’s breathable membranes last longer and reduce glare. Should small chips appear, color-matched patch kits let homeowners tackle quick repairs between backyard parties. That flexibility makes stamped concrete an evergreen choice among budget-minded Boynton Beach pool deck builders on call.

Porcelain paver innovation sleek lines low maintenance

Porcelain paver pool deck systems revolutionize outdoor design with rectified edges and precise thickness tolerances. Factory-applied glazes duplicate limestone, wood, or raw concrete, offering cohesive palettes for sophisticated South Florida backyard makeover ambitions. Because porcelain absorbs minimal water, freeze-thaw damage becomes irrelevant, and mildew struggles to gain purchase. Homeowners applaud the low maintenance pool deck finishes that only need occasional sweeping and a mild detergent rinse.

Engineers also praise porcelain for its high compressive strength, enabling thinner panels that lighten structural loads. According to leading general contractors in South Florida, these lightweight modules accelerate installation over adjustable pedestals, hiding conduits for modern pool deck lighting integration beneath. Slip-rated textures ensure safety, while ultraviolet-stable pigments resist fade under searing skies. Combined, these virtues persuade many luxury developments to choose porcelain over natural stone without compromising elegance.

Composite wood and eco-friendly options that defy mildew

Composite wood pool deck boards blend recycled plastics with reclaimed hardwood fibers, creating eco-friendly pool deck solutions that redirect waste from landfills. Manufacturers emboss realistic grain patterns, so lounge areas evoke classic boardwalks without yearly staining rituals. The boards remain splinter-free, a relief for parents supervising barefoot toddlers. Anti mildew pool deck sealer additives bake into every plank during extrusion, defending against Florida’s relentless humidity.

Sustainability extends beyond materials to lifetime performance. Composite decks resist insect damage, chlorine splashes, and sun bleaching better than untreated lumber. Therefore, property owners enjoy longer replacement cycles and smaller environmental footprints. Contractors still design hurricane ready pool deck design framing with stainless screws and hidden clips for clean aesthetics. When boards finally retire decades later, many manufacturers reclaim them for additional product cycles, closing the loop on responsible resource use.

Blending pool coping profiles with modern drainage solutions

Choosing the right coping profile shapes swimmer comfort and water management alike. Bullnose edges remain popular, yet sleek square coping aligns with contemporary architecture dominating recent South Florida pool deck options. Skilled masons execute custom pool coping installation with tight tolerances, ensuring fingers glide smoothly during laps. Underneath, waterproof membranes tie into deck drains that whisk stormwater away before puddles form.

Advanced trench drains employ removable porcelain grates that match surrounding pavers, preserving seamless lines while meeting stringent pool deck drainage solutions codes. Contractors calculate slopes precisely to avoid standing water that could undermine foundations or freeze mechanical components. Integrated slot drains near sliding doors keep interiors dry during sudden downpours. Together, thoughtful coping and drainage harmonize beauty with performance, completing the engineered resilience every discerning homeowner expects.

Engineering Resilience for Tropical Extremes

Engineering Resilience for Tropical Extremes

Hurricane ready deck design anchoring strategies and uplift resistance

South Florida hurricanes create swirling forces that can pry loose an unprepared deck in seconds. Therefore, every hurricane ready pool deck design starts with deep concrete footings tied by epoxy-coated rebar. Certified structural engineers calculate uplift resistance, then specify stainless hold-downs that lock paver systems to reinforced beams. A seasoned South Florida general contractor also selects tropical climate pool deck materials that will not splinter or shatter when framing flexes under gusts. This integrated approach ensures beauty survives even the harshest wind events.

Attention to surface elements matters equally. Contractors stagger expansion joints so wind cannot exploit aligned seams. They bevel coping edges, reducing the chance that airborne debris gains leverage and chips corners. Finally, wireless moisture sensors buried near footings report saturation levels after each storm, allowing proactive maintenance before minor settlement becomes structural failure. Collectively, these tactics make a South Florida contractor your first defense against nature’s fury.

Slip resistant coatings and anti mildew sealers for year round safety

Rainy afternoons often sweep in without warning, transforming bare stone into a skating rink. To prevent mishaps, reputable construction companies apply slip resistant pool deck paint containing ceramic micro-grit that grips wet footwear. They follow with an anti mildew pool deck sealer infused with silver ions that disrupt fungal growth. Together, these layers allow residents to host gatherings confidently even when humidity peaks.

Application timing influences performance. Professionals wait until the slab’s internal moisture drops below five percent, guaranteeing full chemical bonding. They then back-roll coatings into pores, avoiding bubbles that could trap moisture. Annual porosity tests guide reseal schedules, saving homeowners from expensive over-application. Consistent testing demonstrates the meticulous craftsmanship expected from general contractors in South Florida who place safety above speed.

Energy reflective finishes that slash surface temps and protect feet

Barefoot comfort defines a successful pool deck. Energy reflective deck coatings employ infrared-blocking pigments that reflect up to thirty percent more solar radiation than standard sealers. This innovation keeps limestone, coral stone, and stamped concrete up to twenty degrees cooler under direct sun. Homeowners notice immediate relief, while chlorine loss slows because cooler water evaporates less rapidly.

Reflective technology works best when paired with light-toned substrates such as pearl travertine. Installers profile surfaces mechanically, creating micro-anchor points for maximum adhesion. They also add ultraviolet stabilizers, extending finish life even within relentless subtropical sunlight. The result is a low maintenance pool deck finish that rewards families with comfort and long-term savings.

Integrating modern pool deck lighting and smart controls

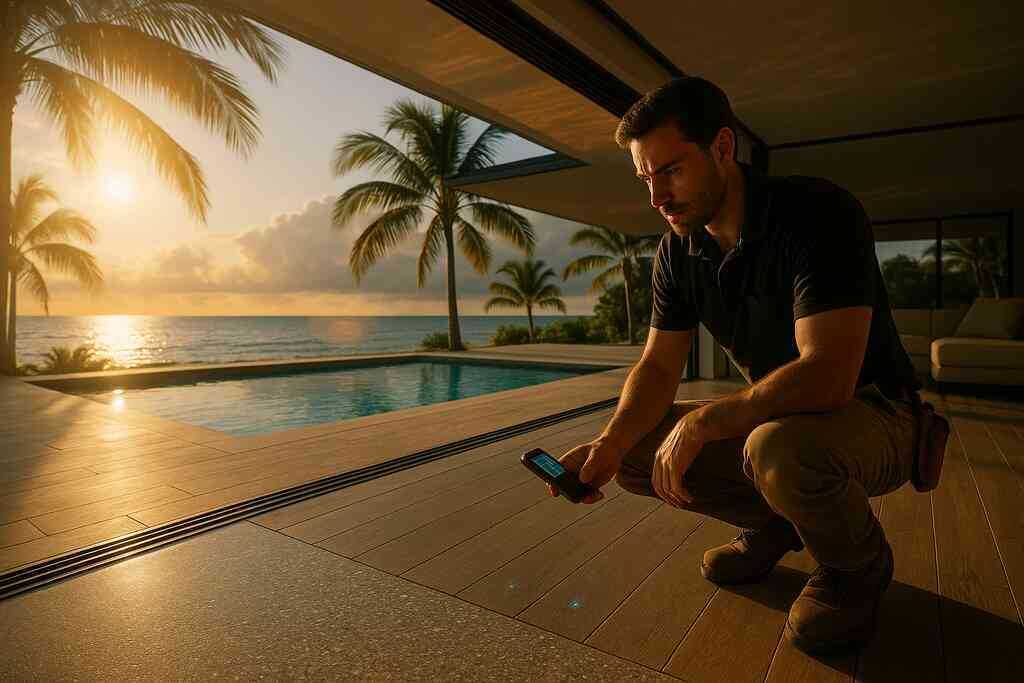

A modern South Florida backyard makeover shines long after sunset thanks to embedded LED strips, flush pathway lights, and app-managed dimmers. Electricians route conduits beneath paver systems, protecting wiring from salt spray and shifting sand. Smart controllers sync with weather forecasts, adjusting illumination when storms approach to conserve power.

Lighting design also boosts safety. Warm lanterns mark elevation changes, while blue edge lights outline shallow beach entries for nighttime swimmers. Integrating seamless automation demonstrates the synergy between a tech-savvy South Florida contractor and vigilant homeowners who insist on effortless lifestyle upgrades.

Low maintenance finishes that thrive in heavy rain and blazing UV

Relentless precipitation alternates with scorching sunshine, punishing inferior coatings. Composite wood pool deck boards encapsulated with polymer shells resist checking, while porcelain pavers shrug off acidic rainwater. Frequent sealing becomes unnecessary, reducing yearly upkeep costs and supporting eco-friendly pool deck solutions.

Maintenance freedom still requires strategic planning. Contractors specify self-cleaning nano sealants on glass tile inlays, allowing storms to rinse away sunscreen residue naturally. They also design perimeter planting beds that filter runoff, limiting dirt buildup on decking surfaces. Consequently, residents enjoy spotless surroundings without exhausting weekend labor.

Sustainable sourcing and recyclable substrates for greener backyards

Eco-conscious Floridians now demand products that honor fragile coastal ecosystems. Ethical suppliers provide FSC-certified composite lumber molded from recycled polyethylene and reclaimed sawdust. Likewise, porcelain pavers contain post-industrial glass that would otherwise head to landfills. These choices lower carbon footprints and qualify projects for municipal green-building incentives.

Construction teams reinforce sustainability through responsible disposal. Old concrete is ground into aggregate, then repurposed beneath new parking areas. Stainless hardware removed during renovation heads to metal recyclers rather than dumpsters. Homeowners who value stewardship often reach out to deck building experts near South Florida pools because they trust transparent supply chains. Ultimately, greener substrates prove that durability, style, and environmental responsibility can coexist on every South Florida pool deck.

Conclusion: Break Ground with South Florida Contractors

Aligning your vision with certified Boynton Beach pool deck builders

Your dream deck begins with clear goals, inspirational images, and an honest budget. Share those details during the first consultation so the builder can translate ideas into material samples and 3-D renderings. Reputable professionals evaluate soil conditions, drainage paths, and surrounding architecture before recommending any surface. This holistic review prevents costly redesigns and ensures the finished space complements your lifestyle from the first cannonball to the final sunset cocktail. When you are ready, reach out to the Boynton Beach pool deck builders on call who consistently rank among the directory’s highest for craftsmanship and communication.

A certified South Florida contractor also helps you prioritize must-have features. For instance, families with young swimmers may value a cool composite surface and extra nonslip coatings. Entertaining enthusiasts often request built-in seating, low-glare lighting, and an adjacent grilling station. Meanwhile, investors typically focus on materials that balance wow-factor with minimal upkeep to protect rental income. Whatever the goal, your builder will break down options by longevity, maintenance, and resale return so you can choose confidently.

Timing your pool deck remodel to optimize cost and climate

Planning projects around regional weather patterns is more than a convenience; it is a structural safeguard. Dry months allow concrete to cure evenly, pavers to lock tight, and sealers to bond without surprise showers. Contractors order materials early, avoiding peak-season price spikes and back-order delays. This foresight keeps crews on schedule and wallets intact, even when supply chains fluctuate. Aligning the calendar with the forecast ultimately delivers a sturdier deck and a smoother build experience.

Contractors also coordinate county inspections and permitting windows. Approvals move faster when offices are less inundated, shortening overall timelines. Reduced downtime translates into fewer labor hours, lowering overhead that might otherwise inflate your invoice. Finally, scheduling during shoulder seasons helps protect neighboring landscaping from heavy equipment stress. These strategies demonstrate how a knowledgeable South Florida general contractor balances quality, economics, and environmental stewardship in one integrated plan.

Next steps to connect with a top ranked contractor near you through South Florida Contractors

Starting is simple: enter your zip code on the directory homepage and filter by specialty. Robust profiles showcase licenses, insurance proofs, photo galleries, and verified reviews, letting you compare talent at a glance. Once you shortlist contenders, click the call button for immediate contact or request a virtual walk-through if traveling. Most professionals provide itemized estimates within days, empowering you to evaluate scope, value, and rapport before signing.

After selecting your partner, use the directory’s project dashboard to track milestones, approve change orders, and store warranty documents in one secure portal. Transparent communication keeps surprises at bay and positions every stakeholder for success. When the final inspection passes, you will own a dazzling, hurricane-ready pool deck that elevates everyday living. From first click to final splash, South Florida Contractors remains your trusted guide for building excellence close to home.

Frequently Asked Questions

Frequently Asked Questions

Question: What makes a travertine paver pool deck one of the best heat resistant pool decking choices in South Florida?

Answer: Travertine’s naturally porous structure allows hot air to vent away instead of storing heat, so surface temperatures stay up to 20 °F cooler than standard concrete-perfect for bare feet in Boca Raton, Delray Beach, or West Palm Beach. Certified South Florida Contractors source premium-density travertine, set each stone over a reinforced base, and seal the surface with an energy reflective deck coating that further reduces heat gain. The result is a long-lasting, non-slip pool deck surface that pairs classic beauty with practical comfort under our tropical sun.

Question: How do South Florida Contractors guarantee a safe, non-slip pool deck surface when I choose stamped concrete or cool deck resurfacing?

Answer: First, our network of general contractors in South Florida profiles the existing slab, repairing cracks before applying a polymer-modified overlay. While the material is still plastic, we broadcast silica grit or ceramic beads for traction that exceeds local code. Next, a slip resistant pool deck paint and anti mildew pool deck sealer lock that texture in place, preventing sunscreen, salt, or sudden rain from turning the deck slick. This multi-layer system delivers a durable, low maintenance pool deck finish that keeps families, guests, and pets secure year-round.

Question: In the article What Are Best Pool Deck Options by South Florida Contractors, luxury materials like marble and porcelain are highlighted-how do I decide which option fits my budget and climate needs?

Answer: Think of marble as resort-level elegance and porcelain as sleek modern practicality. Marble pool deck installation provides unmatched visual drama but needs more frequent sealing to protect against saltwater and sunscreen. Porcelain paver pool decks, on the other hand, deliver rectified edges, high slip ratings, and almost zero maintenance. A South Florida contractor will present cost comparisons, temperature tests, and 3-D renderings, then factor in lifestyle goals-rental ROI, family use, or resale value-so you invest wisely without sacrificing style.

Question: Can South Florida Contractors design a hurricane ready pool deck with low maintenance finishes for my Boca Raton home, and how long does construction typically take?

Answer: Absolutely. Our Boca Raton pool deck builders anchor footing cages with epoxy-coated rebar, specify stainless hold-downs for uplift resistance, and stagger control joints so wind can’t exploit seams. We often pair porcelain pavers or composite wood pool deck boards with custom pool coping installation and hidden trench drains for effortless care. A standard 800-1,200 sq ft project runs 3-5 weeks from ground-break to final inspection, weather and permitting considered. Throughout the build, you can track milestones in the South Florida Contractors project dashboard, ensuring transparency and peace of mind.

Engineering Resilience for Tropical Extremes

Engineering Resilience for Tropical Extremes Frequently Asked Questions

Frequently Asked Questions